The building blocks of at-home diagnostics: swab sticks, sample integrity, and packaging explained

Across houses worldwide, a healthcare transformation is taking place that was barely conceivable a decade ago. Every day, millions of people unseal sterile packages, extract precisely engineered medical swabs, and collect diagnostic samples with confidence—effectively turning their private spaces into extensions of the clinical laboratory.

This shift from institutional to home-based testing represents a profound evolution in healthcare delivery and patient empowerment. Beyond the pandemic-driven spotlight on COVID-19 testing lies a rapidly expanding ecosystem of at-home and point-of-care diagnostics that's reshaping patient care from infectious disease detection to genetic screening.

What makes this revolution possible isn't just digital technology or changing healthcare policies—it's the sophisticated engineering behind seemingly simple tools: medical swabs and their packaging. These unsung components have become the foundation upon which a more accessible, patient-centered healthcare system is being built.

Consumer preferences driving market expansion

The surge in at-home testing adoption stems largely from shifting consumer expectations around healthcare convenience. Today's patients, accustomed to on-demand services in other aspects of their lives, increasingly seek healthcare solutions that minimize disruption to their daily routines.

The contemporary healthcare consumer values the privacy and autonomy that self-testing provides, particularly for sensitive health concerns. Moreover, the integration of digital health platforms with home diagnostic tools creates a seamless experience where patients can not only collect specimens and receive results independently but also connect with healthcare providers for interpretation and follow-up care without leaving home.

This convergence of healthcare delivery with technological convenience has proven particularly appealing to younger demographics and those in underserved or remote areas where traditional healthcare access may be limited.

Innovation powering accuracy and accessibility

The reliability of at-home diagnostics has improved significantly due to advancements in technology. Microfluidic platforms allow for the complex analysis of small samples, while cutting-edge biosensors offer sensitivity that closely mirrors laboratory standards. These innovations are making rapid, reliable testing possible outside traditional clinical settings.

In parallel, design improvements are enhancing usability. Clear, intuitive instructions and error-proof collection systems ensure that even non-specialist users can achieve accurate results. As a result, modern test kits are not only more precise but also more accessible to a broader audience.

Swab sticks: essential tools for reliable testing

At the core of most at-home diagnostic kits is a simple yet highly engineered component: the swab. No longer basic cotton applicators, today’s swabs are designed with specific materials and structures to meet different diagnostic needs. For respiratory illnesses such as COVID-19, flu, and strep, swabs made of nylon, polyester, or foam are commonly used for their superior sample absorption and release properties.

Buccal swabs, often made with flocked nylon, are optimized for DNA and ancestry testing, while nasopharyngeal swabs continue to be critical in respiratory diagnostics. Each material and form is selected to improve patient comfort, ensure sample integrity, and maximize test sensitivity.

Material innovation supporting diagnostic performance

Swab design has evolved in parallel with improvements in materials science. Flocked swabs, featuring vertically aligned nylon fibers, allow for better collection and release of viral or bacterial material. Compared to traditional cotton, synthetic materials such as polyester and foam offer improved sterility and avoid the contamination risks associated with natural fibers.

Material properties are now tailored to the type of analyte being collected—from respiratory pathogens to saliva to wound exudates. These enhancements directly contribute to better test performance and more reliable diagnostic outcomes.

Packaging as a pillar of product integrity

While often overlooked, packaging is a critical component of diagnostic reliability. Individually sealed, sterile packaging ensures that swabs and reagents maintain integrity until the moment of use. With more diagnostic tools being used outside controlled clinical environments, packaging must guarantee sterility and ease of use, while also aligning with regulatory and sustainability requirements.

Solutions such as paper-based blister packs, peelable pouches, and eco-friendly materials are emerging as standard in the industry. These innovations improve user experience and reduce environmental impact without compromising product protection.

Complete tests kits packed in one single pouch

As diagnostics evolve toward more comprehensive, self-contained kits, the complexity of packaging increases. Complete test kits must house multiple reactive components—each with different stability needs—while supporting an intuitive and error-proof testing process. Packaging must be more than a container: it becomes an enabler of usability and accuracy.

Manufacturers are responding with innovative packaging solutions that allow all elements of the test to be protected and presented in a user-friendly format. The ability to pack complete kits in a single pouch, while maintaining sterility and usability, is becoming a key requirement in the industry.

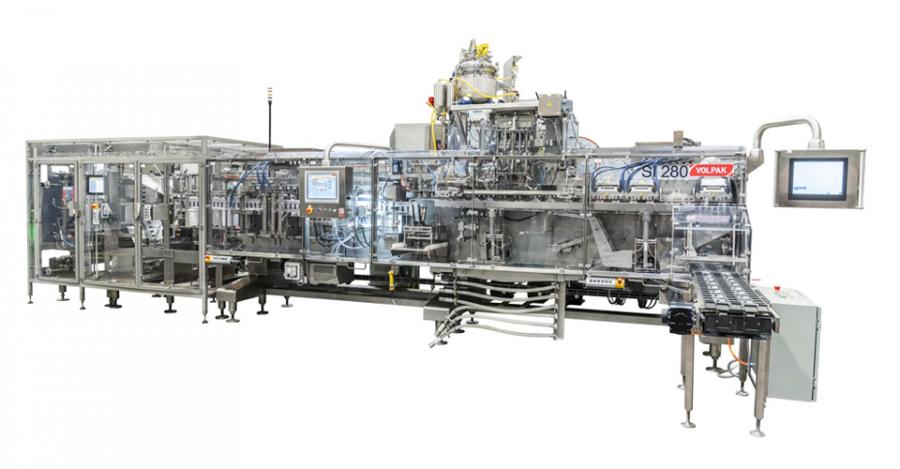

This is where Volpak expertise’s comes in. We specialize in designing complete swab stick feeding and packaging systems that support both product performance and market readiness—ensuring that innovation at the user level is matched by excellence in manufacturing.

Toward a sustainable and patient-centered future

The expansion of at-home diagnostics poses sustainability challenges, particularly due to the single-use nature of most components. However, it also creates opportunities for innovation. Biodegradable swabs, compostable plastics, and recyclable packaging formats are increasingly being developed to meet both regulatory expectations and consumer values.

Sustainability, alongside reliability and usability, is becoming a core requirement in diagnostic design. By integrating eco-conscious materials and formats without compromising sterility or functionality, the industry is laying the groundwork for a more responsible healthcare model.

Embracing complexity to unlock healthcare potential

What began as a response to a global health crisis has become a permanent shift in how diagnostics are delivered. The convergence of personalized medicine, digital tools, and user-friendly formats has transformed the role of at-home testing.

Medical swabs and packaging solutions are no longer peripheral elements—they are foundational to delivering safe, accurate, and accessible care outside traditional settings. For healthcare professionals, R&D teams, and packaging engineers, understanding the technical and operational demands of this new landscape is key to unlocking its full potential. The future of diagnostics depends not only on scientific progress, but on how effectively we can package it.